Meet Partner: DITF - German Institutes of Textile and Fiber Research

Who we are

The DITF (Deutsche Institute für Textil- und Faserforschung, German Institutes of Textile and Fiber Research, foundation under public law) were founded in 1921, and are currently the largest textile research center in Europe. Located in Denkendorf (Germany), the institutes work along the complete textile value chain from molecule to product – and back from textile product to molecule, in order to contribute with new and enhanced fibers, textile materials, & products and textile processes.

The DITF lead research and development on new high-performance fibers and materials, on novel and adaptive processes in fiber, yarn and fabric production, and in textile finishing and textile functionalization. Additionally, the potential of digital information and communications technologies are used for textile industry, including industry 4.0 concepts, and lifecycle assessment to improve circular economy. In all research areas, modern technologies in laboratory and industrial scale are used, covering around 25.000m² of laboratories and technical infrastructure.

The research center employs around 250 scientists, technicians and laboratory assistants. They handle with the latest findings in fundamental and application-oriented research for the textile industry, and set new standards with their own developments. This is not only applied to materials and products but also to production technologies, analytical methods and digital technologies, covering all the textile chain. Therefore, the DITF offer collaborative research and development, industrial projects, as well as testing and consultancy services, and education through various partnerships with the University of Stuttgart and further higher education organizations.

Image Credits: DITF

What we contribute to TRICK

Sustainability plays a central role in the DITF strategy. Firstly, novel textiles contribute with their light-weight properties and/or smart functionalities to save energy during application. Secondly, digital information and communication technologies enable optimzing products and production processes and thus to reduce the environmental load. Thirdly, new processes for textile recycling will close one gap in the circular textile economy.

Image Credits: DITF

Finally, to pave the way towards the circular (textile) economy, transparency and traceability in terms of: What is in my textile? Who made it how? Where does it come from? What shall I do with when I no longer need it? Digital communication and cooperation along the value creation stages is absolutely necessary. Therefore, for more than 20 years the DITF has developed concepts, methods and (IT) tools to enable this, from an IT and an organizational point of view: which data to communicate with whom in which detail.

Image Credits: DITF

Our task

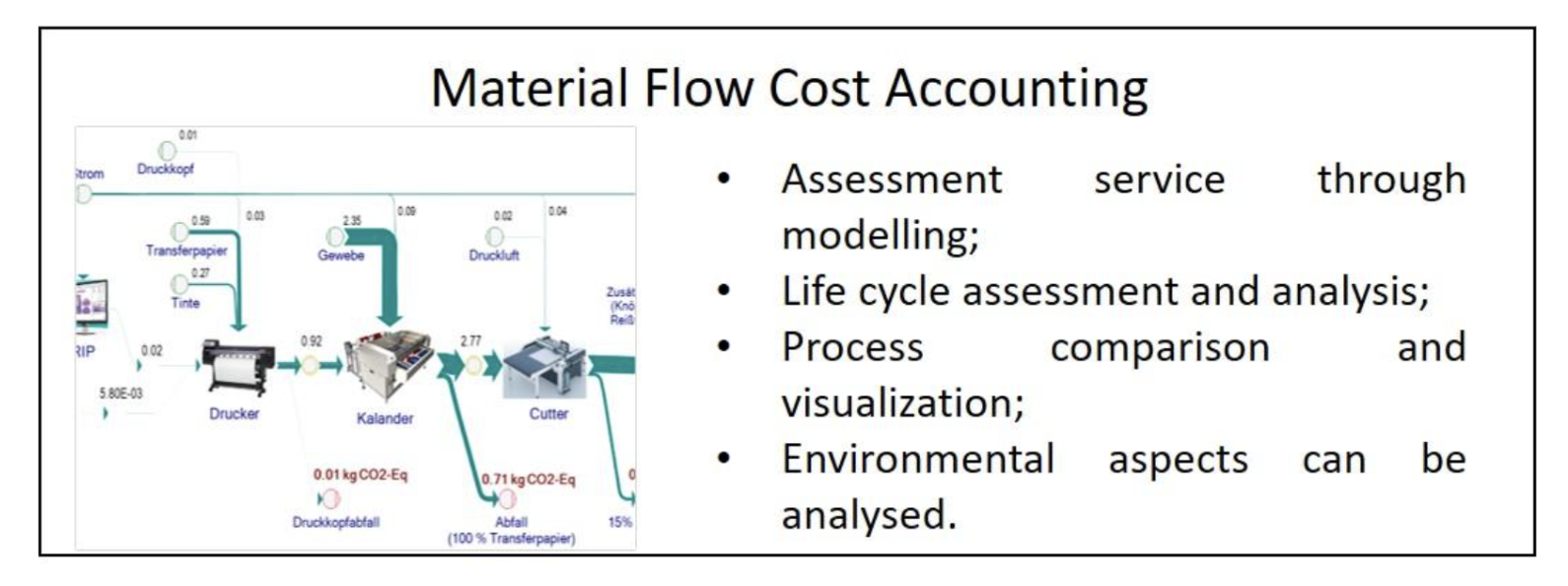

In the TRICK project the DITF focus firstly on modelling, determining and communicating the material flow along the textile value creation stage, from raw material to intermediate materials to products, and – important – including always waste and by-products. Therefore, the DITF textile process models based on the material flow cost accounting method (MFCA, ISO 14055) are used. Complementary also economical aspects as well as environmental aspects (such as CO2 emission) can be considered.

Image Credits: DITF

Secondly, the material circularity of the product will make be assessable by using the Material Circular Indicator (MCI, co-created by EllenMcArthur foundation) concept. The approach is to collect and assess all information about the material flow, including the recycling and reused path.

These methods will be made available as a service on the targeted TRICK marketplace, making use of the TRICK platform and the data. The activity will be harmonized with further analytics and assessment in the context of the LCA service/PEF service and the health service.

In addition, based on the comprehensive experience of the DITF within collaborative EU projects, we contribute with networking and a collaborative work style within the various partners of the project consortium, thus contributing to the efficiency and success of TRICK.

Links

- Website (link)